It is suitable for many materials, large crushing ratio, energy saving and environmental protection, strong and wear-resistant, and convenient to disassemble and replace.

Product Size: D50:1-25μm

Production Capacity: 2~7500kg/h

Feed Size: < 3mm

Material Handling: Widely used in cement industry, new construction industry, black and non-ferrous metal mineral processing, glass ceramics and other production industries.,etc

Reading Volume:

marketing@alpapowder.com

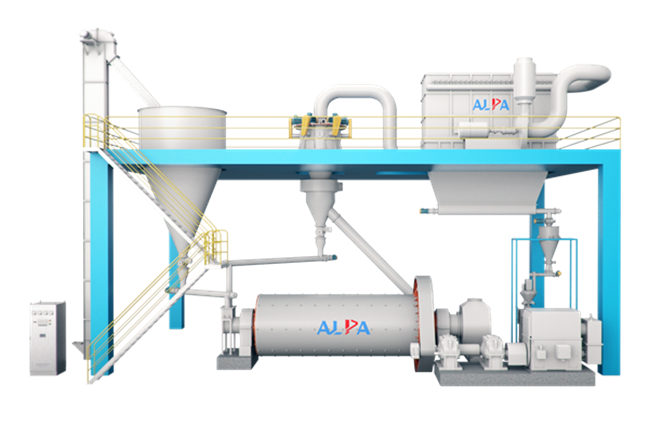

Dry grinding ball mill can be divided into dry grinding ball mill and wet ball mill according to different media, among which the former has more perfect performance, most functions and lower energy consumption, and in the process of purchasing, users also tend to choose dry ball mill, the equipment can grind and process various metal ores, metal oxide, nonferrous metal ores and ferrous metal ores, and plays a very important role in metallurgy, machinery, building materials, coal mines and other fields, this article introduces this device in detail from the following aspects.

Performance advantages of dry grinding ball mill

1. Because the structure of this equipment is very reasonable, and the connection between various components is very compact, its volume is smaller, and it will be easier to maintain and use.

2. Because its motor power is very high, its production capacity is quite large, so its production capacity will be higher, and the benefits created for users will be higher.

3. The equipment is equipped with energy-saving and environment-friendly devices, and all kinds of noise are effectively suppressed, so it is a modern popular energy-saving and environment-friendly mineral processing equipment.

4. The quality of such equipment is excellent, and the selection of materials is very strict, so this is a high quality equipment, so its service life is longer.

This equipment mainly consists of hardware, software and auxiliary devices. The main contents are as follows:

1. Hardware part: hardware is the foundation of equipment, and its main components include Feeder, motor, casing, transmission device, gear, etc, the hardware configuration is closely related to its service life.

2. Software part: This is the software control part of the equipment, and the more developed the software part is, it shows that the automation degree of the equipment is high, and the technology content is very high, so it will save more time and effort for users to operate.

3. Auxiliary device: in order to improve the function of the equipment, the equipment is installed with many auxiliary devices, such as protection circuit, energy saving device and noise elimination system, so it can be better used by users.

Source of Technology

Germany technology, international standard non-metallic minerals production line.

Technical Process

The process mainly includes crushing(generally use two stages of crushing), grinding, classifying, package, magnetic separation, transportation, lifting etc. In conjunction with several classifiers in parallel or series, several different products can be obtained at the same time.

Ball Mill

Special design to ball mill which will be selected on the basis of material’s hardness, grindability index, final particle size and capacity. The shape of the lining and the ball (segment) are tailored according to years of engineering practice experience to maximize the grinding efficiency of the ball mill and reduce the energy consumption.

Classifier

Different models of Classifier could be selected depending on different fineness of products. FW series Classifier are suitable for classifying of D97:3~20μm products, FL series for classifying of D97: 8~45μm products. Wide range of adjustment is available with each Classifier and the application is extensive in market.

Flexible control of product particle size

The production line are designed and optimized to match with several classifier in series, the particle size can be controlled, and several products can be obtained at once, low energy consumption, free from over-crushing.

Low noise and emission

Environment protection design to the vibration damper, component soft connection and filter bag result in lowering noise and dust.

Automatic Control

The electric control system employs programmed control for the entire process from feeding, classifying and grinding to packing.

Personalized customization

According to the customer’s investment scale, we can design different plant structures and equipment layout schemes to provide the most cost-effective configuration system. For example, the equipment layout with an annual output of less than 20,000 tons is mostly arranged in a single-storey factory layout, and the conveying system adopts spiral conveying. The equipment layout of the scale of more than 20,000 tons adopts the multi-layer factory three-dimensional arrangement, the conveying system adopts pneumatic conveying, and the packaging adopts automatic packaging and equipped with palletizing system.

Provide value-added services

Add-on services to customer such as mineral processing, modification, granulation and equipment upgrading.