Widely used in cement industry, new construction industry, black and non-ferrous metal mineral processing, glass ceramics and other production industries.

Product Size: D50:1-25μm

Production Capacity: 2~7500kg/h

Feed Size: < 5mm

Material Handling: Calcium carbonate, Paper Spar, marble, limestone, feldspar, Dolomite,etc

Reading Volume:

marketing@alpapowder.com

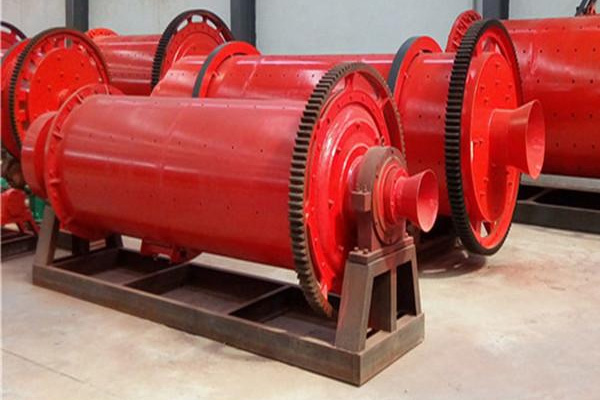

Rod mill ball mill is a kind of mill in which the grinding body is steel rod. Rod mill ball mill generally adopts wet overflow type, which can be used as first-class open circuit grinding and is widely used in first-class grinding of artificial stone sand, mineral processing plant and chemical plant power department. The mill mainly consists of motor, main reducer, transmission part, cylinder part, main bearing, slow transmission part, feed part, discharge part, annular seal, thin oil lubrication station, big and small gear jet lubrication, basic part, etc.

Source of Technology

Germany technology, international standard non-metallic minerals production line.

Technical Process

The process mainly includes crushing(generally use two stages of crushing), grinding, classifying, package, magnetic separation, transportation, lifting etc. In conjunction with several classifiers in parallel or series, several different products can be obtained at the same time.

Ball Mill

Special design to ball mill which will be selected on the basis of material’s hardness, grindability index, final particle size and capacity. The shape of the lining and the ball (segment) are tailored according to years of engineering practice experience to maximize the grinding efficiency of the ball mill and reduce the energy consumption.

Classifier

Different models of Classifier could be selected depending on different fineness of products. FW series Classifier are suitable for classifying of D97:3~20μm products, FL series for classifying of D97: 8~45μm products. Wide range of adjustment is available with each Classifier and the application is extensive in market.

Rod mill ball mill is an asynchronous motor connected with pinion through reducer, which directly drives the surrounding gear wheel to slow down and rotate, drives the rotating part to rotate, and the cylinder is equipped with appropriate grinding medium-steel rod, under the action of centrifugal force and friction force, does the material to be ground continuously enter the inside of the cylinder from the feeding part and be crushed by the moving grinding medium, and the product is discharged out of the machine through overflow and continuous feeding force for the next stage of process processing.

There are roughly three uses of rod mill:

1) tungsten and tin ore and other rare metal minerals gravity or magnetic separation plants often use rod mill in order to prevent the harm caused by over-crushing;

2) when the second stage grinding process is used, if the first stage is ground from 20~6mm to 3~1mm, and Rod grinding is used as the first stage grinding equipment, the production capacity is relatively large, the efficiency is also high. Because the surface area of Rod charge with a certain weight is much smaller than that of ball charge with the same weight, the productivity and efficiency of Rod grinding are lower than that of ball milling when making the second stage fine grinding;

3) in some cases, it can replace short cone ore crusher for fine crushing. When handling softer or less hard ores (especially those with high viscosity) and grinding 19-25mm (even 32mm) ore to 6-10 mesh with rod mill, the configuration is simpler and the cost is lower than that when using short cone ore crusher and screen to form a closed circuit, and the dust removal in the crushing workshop can be simplified. For hard mineral, it may be more economical to use short cone ore crusher to close the circuit with the sieve. In the design, whether to use ball milling or Rod grinding for election can be determined only by making plans according to specific conditions.

Rod mill ball mill is widely used in metal and non-metal mines, water conservancy and building materials departments to grind various ores or rocks.