The products are characterized by small wear, high precision control and uniform particle size distribution. It can be widely used in micron scale experiment and production of superhard materials such as synthetic diamond and boron nitride.

Product Size: D50:1-25μm

Production Capacity: 2~7500kg/h

Feed Size: < 3mm

Material Handling: Quartz, silica, quartz powder,etc

Reading Volume:

marketing@alpapowder.com

Widely used in cement industry, new construction industry, black and non-ferrous metal mineral processing, glass ceramics and other production industries.

Source of Technology

Germany technology, international standard non-metallic minerals production line.

Technical Process

The process mainly includes crushing(generally use two stages of crushing), grinding, classifying, package, magnetic separation, transportation, lifting etc. In conjunction with several classifiers in parallel or series, several different products can be obtained at the same time.

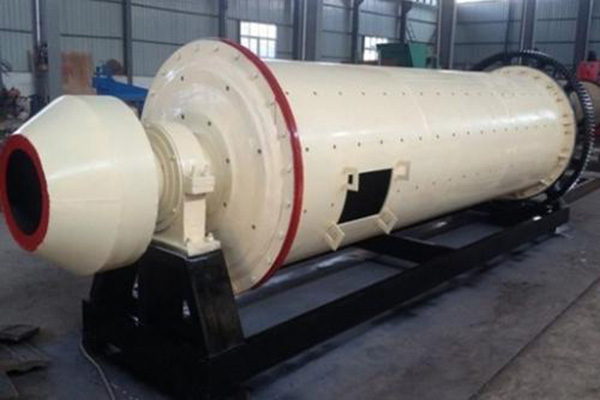

Ball Mill

Special design to ball mill which will be selected on the basis of material’s hardness, grindability index, final particle size and capacity. The shape of the lining and the ball (segment) are tailored according to years of engineering practice experience to maximize the grinding efficiency of the ball mill and reduce the energy consumption.

Classifier

Different models of Classifier could be selected depending on different fineness of products. FW series Classifier are suitable for classifying of D97:3~20μm products, FL series for classifying of D97: 8~45μm products. Wide range of adjustment is available with each Classifier and the application is extensive in market.

The main function of steel balls in ball mill is to impact and crush materials, and also play a certain grinding role. Therefore, the purpose of steel ball grading is to meet the requirements of these two aspects. The grinding effect directly affects the grinding efficiency, and ultimately affects the output of ball mill. Whether the grinding requirement can be reached depends on whether the grading of steel ball is reasonable, mainly including the size of steel ball, the number of ball diameter series, the proportion of balls of various specifications, etc.

Large-scale, intelligent, energy-saving, low-carbon, and environmentally friendly are the missions and responsibilities that the times have given us.

1. Reasonable process design, low energy consumption per unit, large output.

2. PLC control, easy to operate.

3. Safe and stable operation and low maintenance cost.

4. Flexible choice of grinding media and liners.

5. Low contamination of materials with high purity.

6. The product produced has a concentrated particle size distribution and stable product quality.