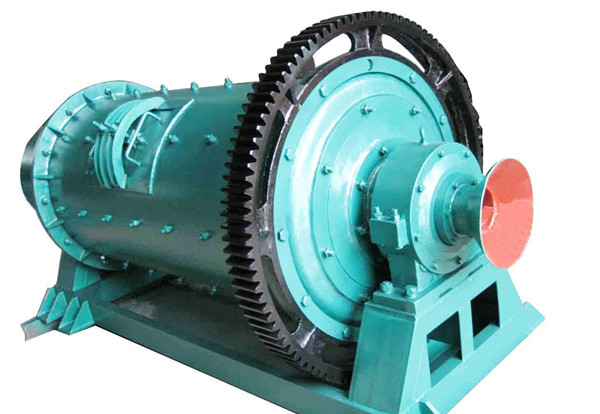

(1) Ball mill checks the size gear. After removing the gear seal, the oil on the large gear and the pin should be thoroughly cleaned. The radial gap of the large gear and the pinion is then measured with a plug (note that the measuring point should be located on the straight line of the point in the gear and the pinion) and measure the gap of the tooth surface. Then use the caliper or gear caliper to measure the pound diameter of the large gear and the pinion. It can also be measured with gear models and plug. The quantity of the measurement is compared to the thickness of the standard tooth.

Install thousands of days, rotate large gears and pinion, {! Bay 0 Measures the axialness and radial oscillation of the gear. Check the gear wear and whether the gear has cracks and record it. (2) Replace the use of large gears and large gears. 1) After removing the upper gear cover of the large gear, turn the half-surface joint surface of the large gear to the horizontal position, and use the crane to halt the upper half of the gear. 2) Removing the large fuel tank fastening bolts and half-face fastening bolts, raise the upper half gear to the designated position and use the wooden mat. 3) Turn the tank 180. Take the other half of the large gear using the same method. 4) Screw the bolt into half of the new large gear. Turn the large can 180. Then put the other half in place with a bolt and tighten the large gear fastening bolt. Use two threads to measure the axial and radial swing values of the gears and record them. 5) When the radial vibration is unqualified, the lateral gasket should be analyzed and adjusted according to the record. Tighten after adjustment, then measure until qualified. 6) When the axial swing is unqualified, first check if the flange joint surface of the large fuel tank is tightened and determine if it is a spare piece error or installation error. 7) After the large gear is passed, find the pin hole on the original slot. If you fail, replace the pin or increase the pins, and then reassign the nail. 8) The teeth of the large gear and pinion should be less than 30%, the pinion shaft and the radial swing should not exceed 0.25 mm, and the large gear should be swing in the ± 2 mm range. The large gear swing in an inner radial direction of 1 mm. (3) quenching the surface of the gear. When the tooth surface of the gear is worn by 2 to 3 mm, the tooth surface is quenched to increase the hardness of the tooth surface. The bosses formed by the deformation of the quenched tooth surface deformation and the root wear should be flat, the dentity and the teeth should be kept correct (the toothed test can be completed in advance). When the quench gear surface, the gear is flat and the end face of the gear is parallel to the ground. The flanks are heated by the burner, and the burner moves from the bottom along the tooth surface to the top.. When the quenching temperature is reached, turn off the combustor of the combustor, open the cooling water valve, and spray the water on the tooth surface. The material of the large gear is typically 45 # cast steel, and the surface hardness thereof can reach about 350 Brinent hardness after quenching. The material of the pinion is usually 45 # cast steel or 45 # chrome steel. After quenching, the surface hardness can reach the Brinell hardness 400-500. (4) Gear repair welding. When the wear of the gear reaches 1/3 of the tooth thickness, in order to be intermittent, the surface treatment method can be used to compensate for the teeth, and the welding should be processed to maintain the teeth. The shape is correct, then quenched.

API ultrafine pulverization production line for a pharmaceutical company in Guangdong

API ultrafine pulverization production line for a pharmaceutical company in Guangdong

A Mining Group in Shandong Province: New Tin Powder Production Line

A Mining Group in Shandong Province: New Tin Powder Production Line

A heavy calcium carbonate ball milling and grading + modification production line in a mineral facto

A heavy calcium carbonate ball milling and grading + modification production line in a mineral facto

Quartz powder ball mill and air classifier production line in a mineral factory in Shandong

Quartz powder ball mill and air classifier production line in a mineral factory in Shandong

3M new material factory: Resin grinding mill production line

3M new material factory: Resin grinding mill production line