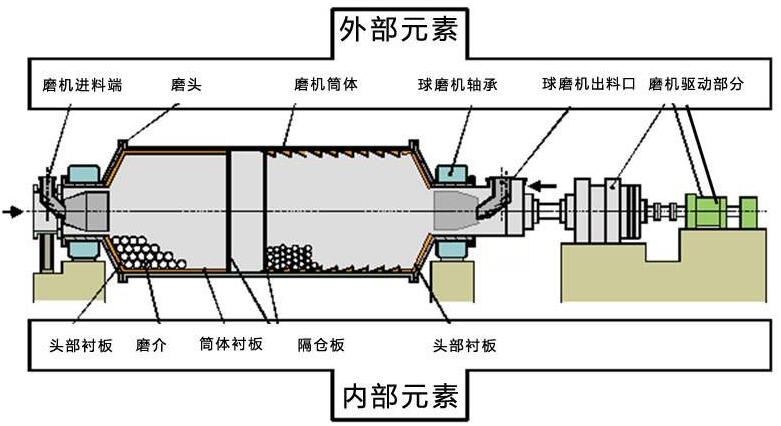

The mining operating energy consumption of mining plant accounts for 45% to 55% of the total energy consumption of the plant, and the production fee is 40% to 60% of the cost-fee fee. Therefore, discussing the way to reduce the energy can be reduced. Extremely practical. At this stage, the mining factory has widely selected environmentally-friendly energy-saving machinery equipment, and the courage to explore new environmentally friendly energy-saving countermeasures has obtained significant economic benefits. The key to reducing the energy consumption of ball mills has the following categories:

1, Plate ball mill instead of overflow ball mill

The square is not only low, but the coal paste is low, but the coal paste is faster, and the iron ore can be broken. There are many balls, and the big ball can be applied, and the ball can also be applied, because the mine is equipped with a square, and the ball is not easily broken by the coal slurry, and the standard can be produced in excellent work. And the square gauge is 20% to 30% higher than the spill type production capacity of the same size, and can save 25% of power engineering.

2, roller bearing replacement rolling bearing

The roller bearing is low, and the functional loss required to penetrate the roller bearing is lower than the rolling bearing. In addition, the roller bearings are under every normal operating conditions, no need to replace the main rolling bearing, save maintenance, maintenance, and improve the operating rate.3, the standard air pressure clutch alternative general clutch

Standard air pressure clutch can be successfully completed, and the motor is started, and the motor is completely started, and when it makes a smooth operation rate, Then, the clutch is fused, and the motor itself can be reduced. It is very easy to start, and the starting current amount is hit by the network, and the one-button installed output power of the ball mill is also reduced.

4, a rubber liner

rubber liner is a non-metallic material, practice activity, and a wet trick mill with high wear resistance. After the rubber liner is selected, the ball grinding machine consumption generally has a certain reduction, which is about 10%, and the production is increased by about 5%. In addition to this, the rubber liner is usually approximately 2 to 3 times the aluminum alloy wear-resistant liner. It is worth mentioning that Xinhai Mine is selected for wet secret recipe design, and the nanotechnology complex decentralized technology is obtained. Features of wear-resistant rubber, with wear resistancePerformance, its use period is 3 ~ 4

API ultrafine pulverization production line for a pharmaceutical company in Guangdong

API ultrafine pulverization production line for a pharmaceutical company in Guangdong

A Mining Group in Shandong Province: New Tin Powder Production Line

A Mining Group in Shandong Province: New Tin Powder Production Line

A heavy calcium carbonate ball milling and grading + modification production line in a mineral facto

A heavy calcium carbonate ball milling and grading + modification production line in a mineral facto

Quartz powder ball mill and air classifier production line in a mineral factory in Shandong

Quartz powder ball mill and air classifier production line in a mineral factory in Shandong

3M new material factory: Resin grinding mill production line

3M new material factory: Resin grinding mill production line